Zero-Clash Automated Hanger Placement

The only Revit add-in that automatically avoids fittings, valves, and obstructions during placement. No manual fixes. No rework. Just clean, code-compliant results.

The only Revit add-in that automatically avoids fittings, valves, and obstructions during placement. No manual fixes. No rework. Just clean, code-compliant results.

Everything you need for efficient hanger placement

Automatically detects AND avoids fittings, valves, flanges, and existing hangers. Other tools only detect - we prevent.

When a clash is found, the algorithm searches step-by-step to find the optimal position. Step size is configurable in CSV rules.

Place hangers on entire fire protection systems with one click. No more tedious manual placement.

Follows NFPA 13, MSS SP-69, FM Global and other industry standards. Always audit-ready.

Automatically calculates rod length to structural elements like floors and beams.

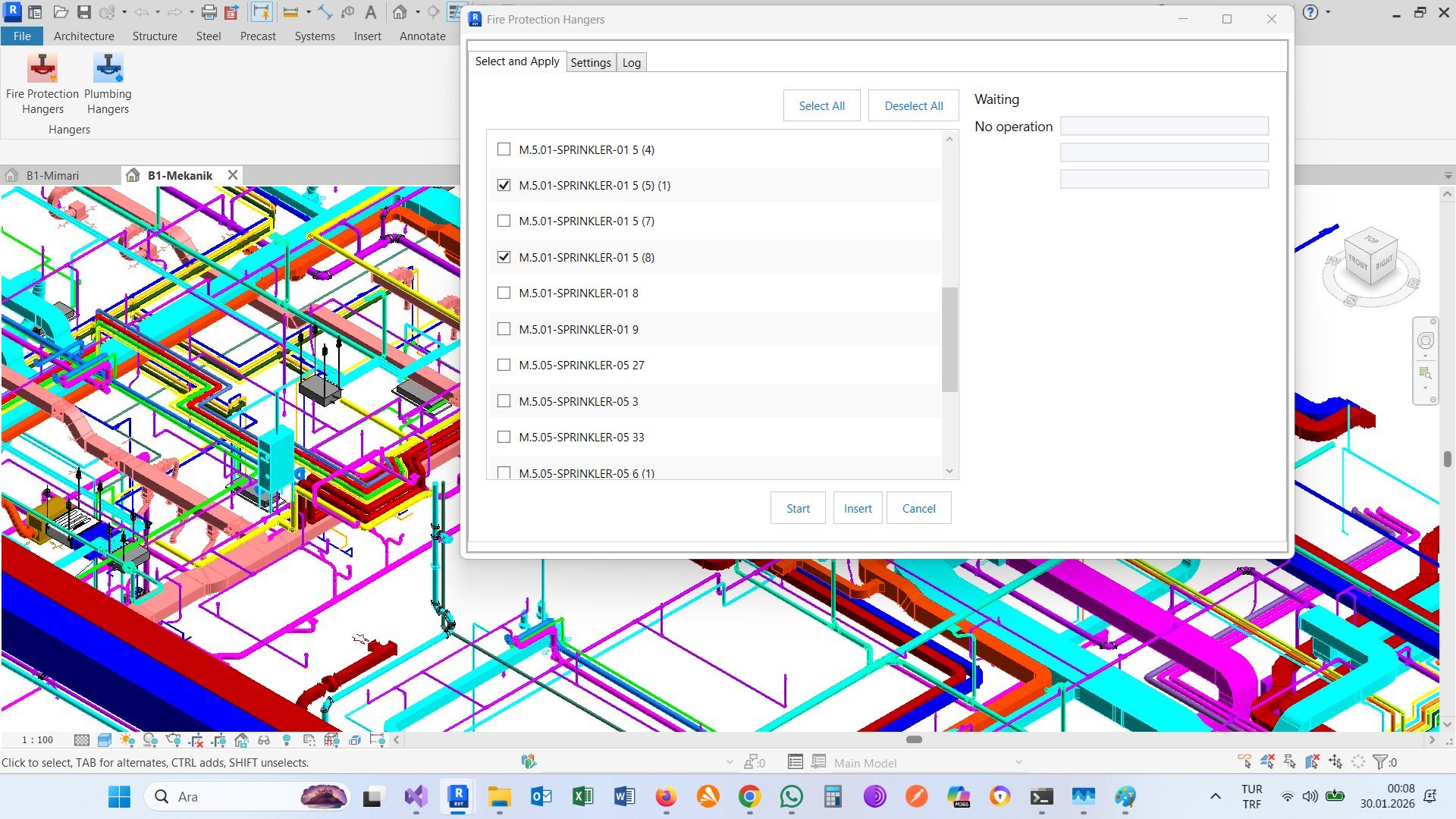

All fire protection systems from host AND linked models appear automatically when you open the app. No manual searching.

Every decision logged: placements, clashes avoided, iterations performed, skipped pipes, and why. Full audit trail for QA/QC.

Assign different hanger families for each pipe diameter. DN25 can use one family, DN100 another. Full flexibility for your project needs.

Other tools detect clashes after placement. We prevent them during placement.

Place hangers at fixed intervals

Run clash detection in Navisworks

Find 50+ clashes with fittings

Manually fix each one

Select systems and click Insert

Algorithm checks each position

Clash found? Auto-iterate 10mm

Clean model, zero clashes

Tees, elbows, reducers, couplings - no hanger will be placed on any fitting

Gate valves, check valves, butterfly valves - all detected and avoided

Flanged connections are identified and given proper clearance

Already have hangers? We won't duplicate or place too close

Checks collision with ALL pipes in the model, not just the host pipe

Beams, columns, and other structural members in linked models

Walls from host and linked architectural models are detected

HVAC ductwork and other MEP elements that may intersect

Configurable minimum clearance from all obstructions

Clash detection works across all linked Revit files - not just the host model. Structural, architectural, and other MEP models are all included in the clash check. True multi-discipline coordination.

Our algorithm intelligently ignores pipe insulation and duct insulation during clash detection. This prevents false positives and ensures hangers are placed based on actual pipe geometry, not insulation layers.

Step 1: Initial position falls on fitting - CLASH!

Step 2: Move by iteration step, check again...

Step 3: Clear position found - hanger placed!

Fully Configurable: IterationStep=10 (mm, adjust as needed) • ClearanceDistance=100 (mm, minimum gap from obstacles)

Four simple steps to automated hanger placement

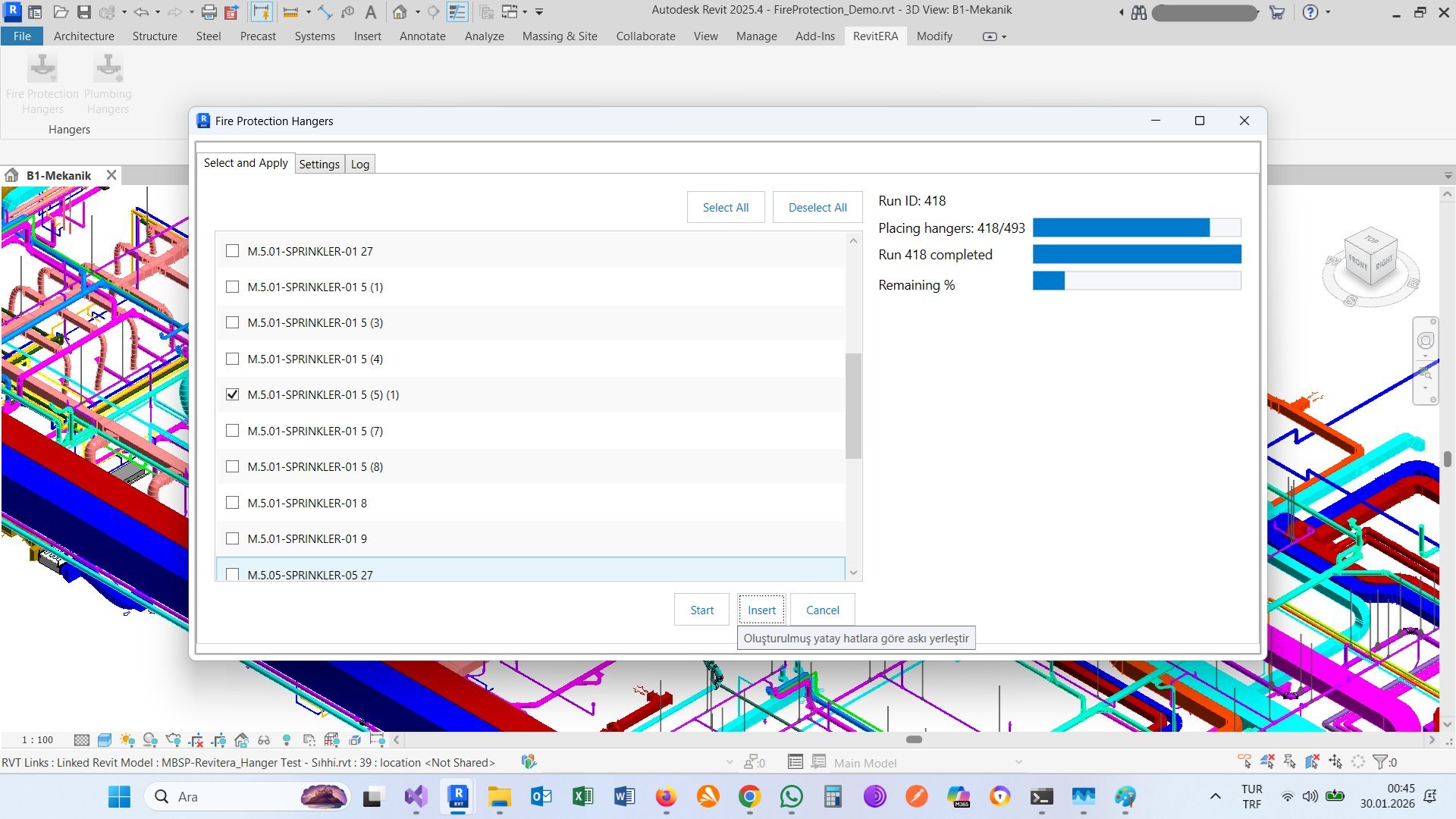

All fire protection systems automatically detected - including linked models

Instant detection: The moment you open the application, it automatically scans your entire Revit project - including all linked files - and lists every fire protection piping system. No manual searching required.

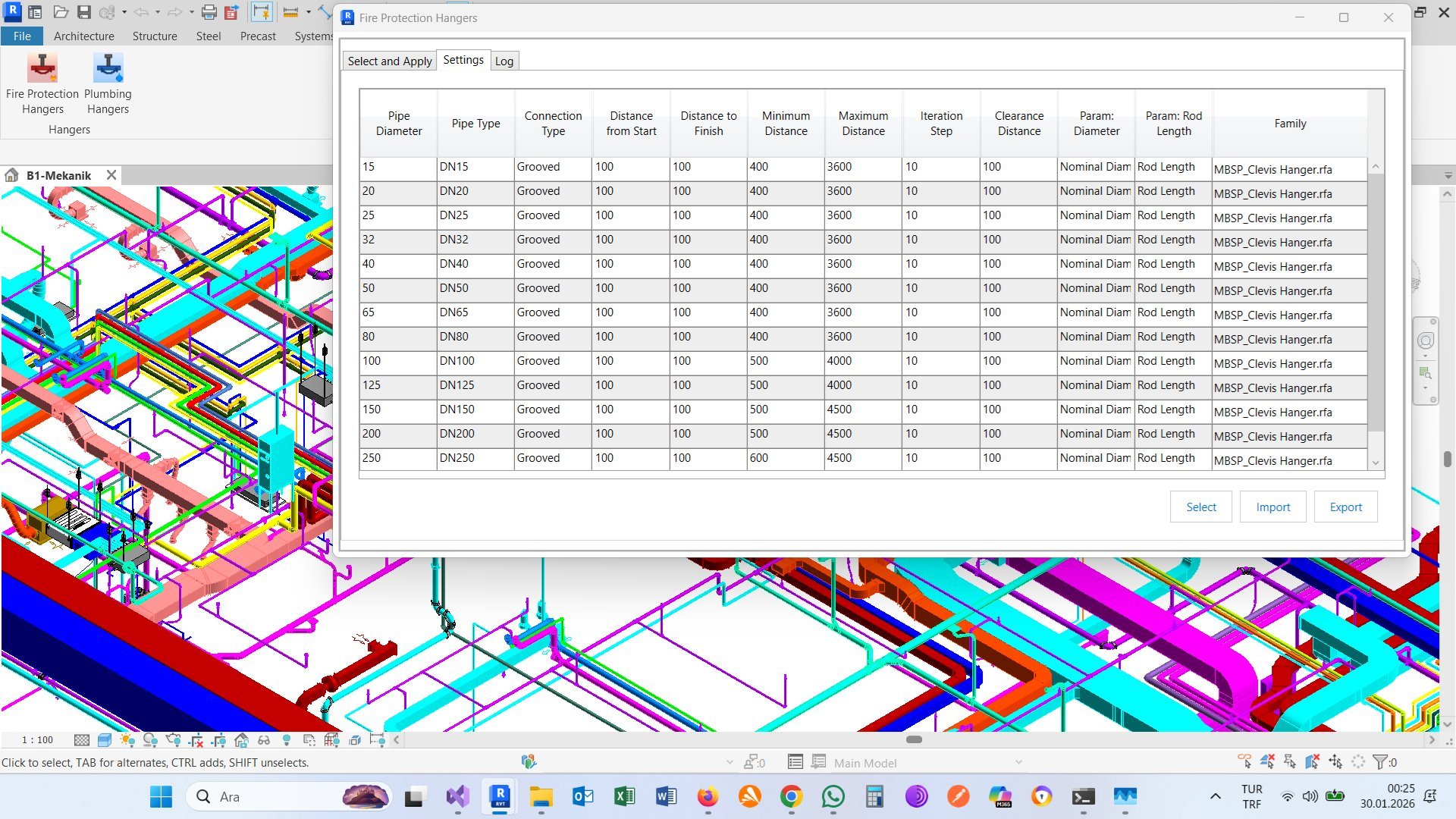

Set spacing, clearances, and hanger families per pipe size

Define placement rules for each pipe diameter using an easy-to-edit CSV file. For each pipe size, you can specify:

Application analyzes pipe runs and extracts placement candidates

The Start button analyzes your selected systems and extracts all pipe runs. During this phase, the application:

Hangers are placed automatically with clash detection

The Insert button performs the actual hanger placement with intelligent positioning. For each run:

Know exactly what happened, where, and why. Every decision documented.

Pipe ID, position, hanger family used, rod length calculated

When clash detected, each step is logged until clear position found. Step size is user-configurable (default: 10mm)

What element caused clash (fitting, valve, wall, duct, etc.) and how it was resolved

Pipes that couldn't receive hangers and why (too short, no matching rule, vertical, etc.)

Total pipes processed, hangers placed, clashes detected, time elapsed

QA/QC Ready: Auditors can verify every placement decision

Easy Debugging: If something looks wrong, check the log to see why

Project Documentation: Keep logs as part of project records

Rule Optimization: See which rules are being applied most often

[14:32:15] ═══════════════════════════════════════════════════ [14:32:15] FIRE PROTECTION HANGERS - Run Started [14:32:15] Selected Systems: 3 | Total Pipes: 247 [14:32:15] ═══════════════════════════════════════════════════ [14:32:16] Processing: Wet Sprinkler - Level 1 (89 pipes) [14:32:16] ─────────────────────────────────────────────────── [14:32:16] Pipe #142587 | DN50 | Length: 4250mm [14:32:16] → Position 1: 850mm - CLASH with Tee fitting [14:32:16] → Position 2: 860mm - CLASH with Tee fitting [14:32:16] → Position 3: 870mm - CLEAR ✓ [14:32:16] → Hanger placed at 870mm | Rod: 2340mm [14:32:16] → Position 4: 3150mm - CLEAR ✓ [14:32:16] → Hanger placed at 3150mm | Rod: 2340mm [14:32:17] Pipe #142592 | DN25 | Length: 1850mm [14:32:17] → Position 1: 450mm - CLASH with Gate Valve [14:32:17] → Iterating... found clear at 620mm ✓ [14:32:17] → Hanger placed at 620mm | Rod: 2180mm [14:32:18] Pipe #142601 | DN20 | Length: 890mm [14:32:18] → SKIPPED: Pipe too short for min spacing (1200mm) [14:32:45] ═══════════════════════════════════════════════════ [14:32:45] RUN COMPLETE [14:32:45] ─────────────────────────────────────────────────── [14:32:45] Pipes Processed: 247 [14:32:45] Hangers Placed: 418 [14:32:45] Clashes Avoided: 52 [14:32:45] Pipes Skipped: 12 [14:32:45] Time Elapsed: 29.4 seconds [14:32:45] ═══════════════════════════════════════════════════

Not just for placing hangers - also a powerful QA/QC audit tool for delivered projects

Place hangers automatically on your fire protection systems with zero clashes.

Validate delivered projects by detecting design errors in existing hanger placements.

Detects hangers incorrectly placed on tees, elbows, reducers

Finds hangers placed on gate valves, check valves, butterfly valves

Identifies hangers that exceed maximum allowed spacing per code

Finds pipe runs that should have hangers but don't

Detects hangers that clash with beams, columns, walls

Hangers too close to fittings or other elements

Receive project model from contractor/subcontractor

Open in Revit and run Fire Protection Hangers

Review detailed log file for all detected issues

Send error report back for corrections

Why engineers choose Fire Protection Hangers

What used to take hours now takes minutes. Focus on engineering, not repetitive tasks.

Automatic clash detection eliminates human errors. No more hangers on fittings or valves.

Pre-configured rules follow NFPA 13, MSS SP-69, and other industry standards.

Design changed? Delete existing hangers and rerun. Hangers update automatically with your model.

Comprehensive logs showing every placement decision, clashes avoided, and issues found.

Complete more projects in less time. Improve your bottom line with automation.

Screenshots from the application

Clean, intuitive interface for system selection and configuration

Easy-to-use settings for spacing rules and hanger families

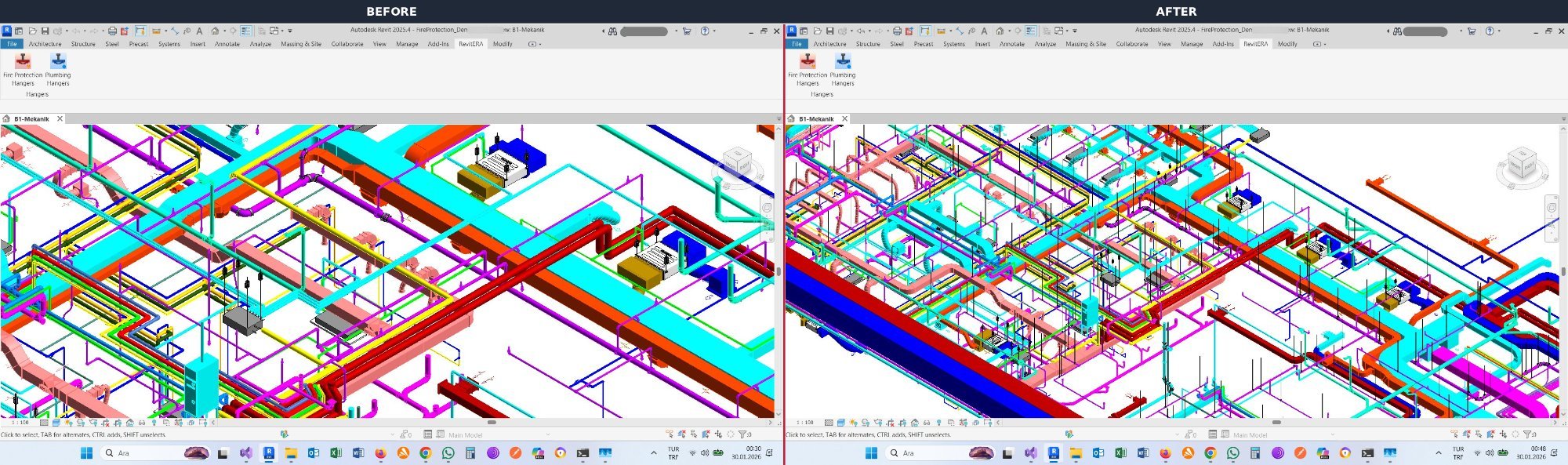

Automatic hanger placement - before and after comparison

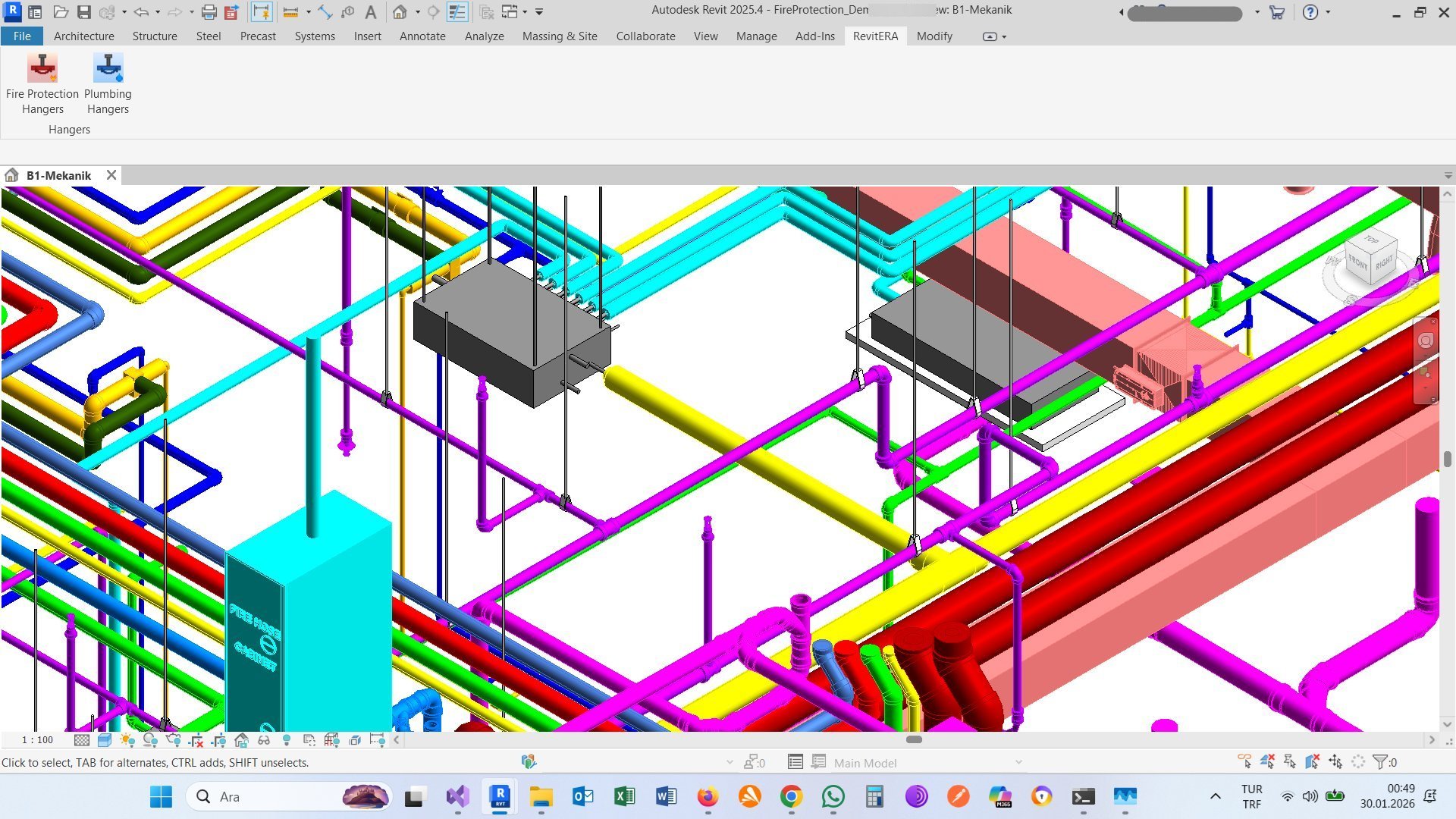

Detailed view showing hangers with rod connections

Real-time progress tracking during placement

Version 2025 or 2026

Windows 10 or Windows 11

Included with Revit 2025+

Download the free demo and try it on your own projects. No credit card required.

Download Free Demo Buy License14-day trial • 50 hangers per day • Full functionality

Join hundreds of engineers who have automated their hanger placement workflow